Category DIY Projects

I seem to be on a roll lately with these ESP8266 based projects, but they are so fun and useful, it’s not difficult to identify new uses. This project originated from another project I just completed, building my own solder… Continue Reading →

Automating my home has been a journey I’ve been on for several years now and at no point in that journey did I feel the necessity for a $200USD doorbell. Not that I don’t see use cases for it or… Continue Reading →

Not all projects are incredibly complex builds, technically challenging, or innovative in their outcomes. This is one of those projects, however, it’s probably one of the few projects that I’ll remember for the rest of my life. Being a maker… Continue Reading →

My wife and I purchased a new home back in June of 2015 and were blessed enough to get a wonderful home (that needed some serious love) and an acre of land in a corner lot surrounded by horse farms…. Continue Reading →

Being a technology geek for me doesn’t stop at writing code or hacking gadgets, it extends to even communications and specifically RF (Radio Frequencies). I’m a licensed HAM radio opeartor and have been for some time now. It’s true that… Continue Reading →

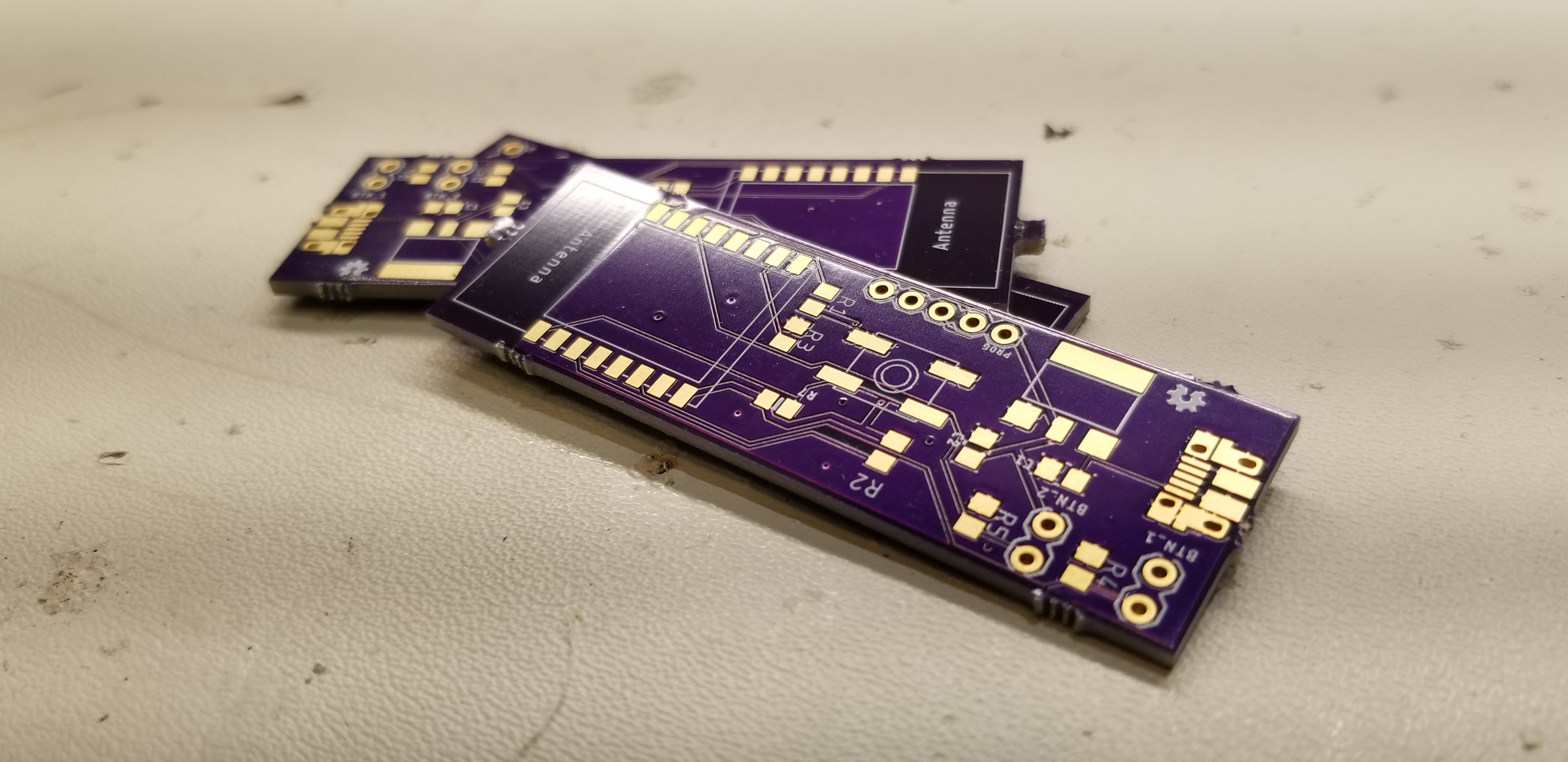

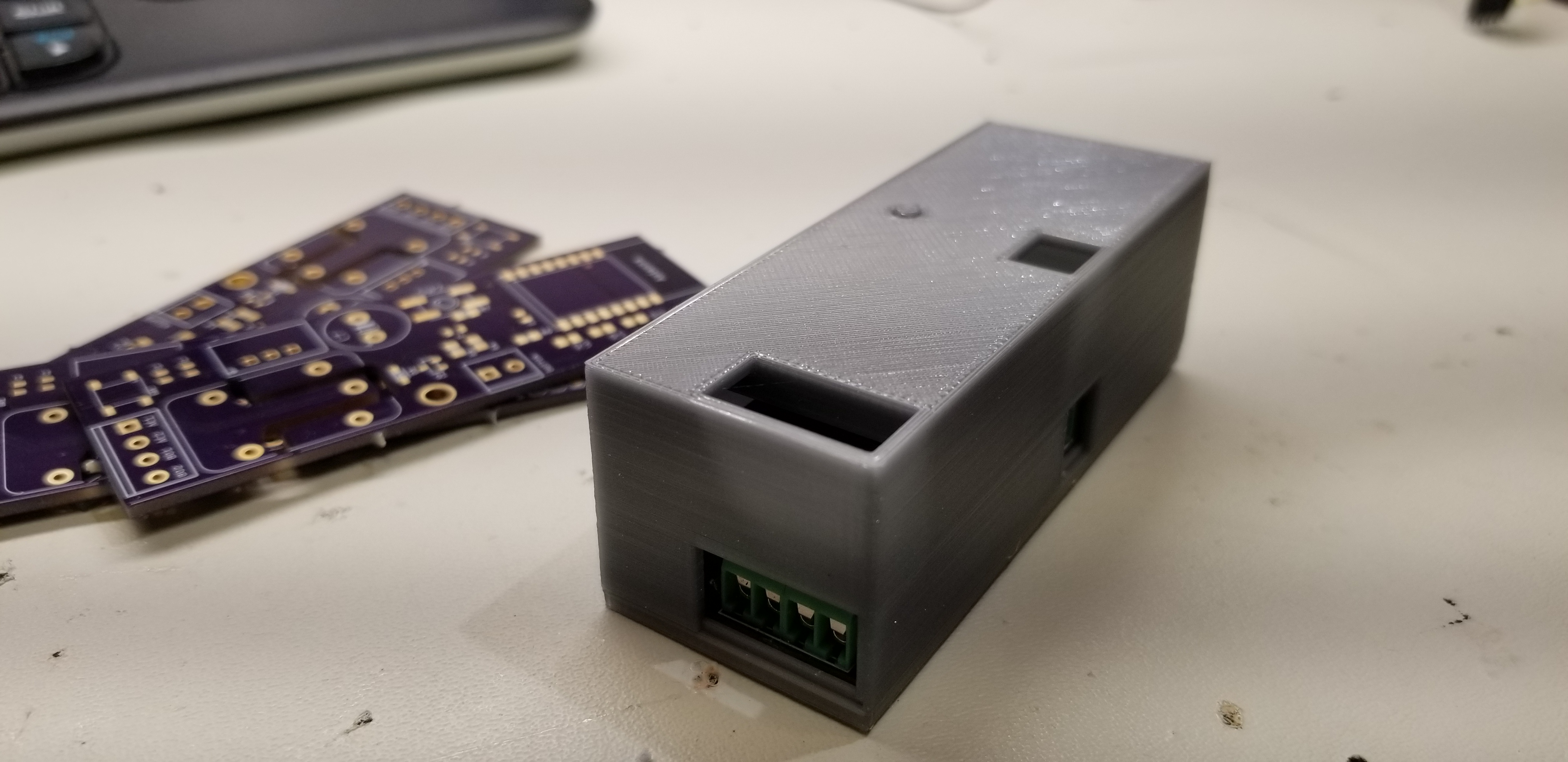

Long title and a large degree of entropy? Nah! This is a system that was built in layers but the components are largely used and fairly niche in their use. I’ve just decided that I’d use them to provide something… Continue Reading →