Category ESP8266

I seem to be on a roll lately with these ESP8266 based projects, but they are so fun and useful, it’s not difficult to identify new uses. This project originated from another project I just completed, building my own solder… Continue Reading →

Automating my home has been a journey I’ve been on for several years now and at no point in that journey did I feel the necessity for a $200USD doorbell. Not that I don’t see use cases for it or… Continue Reading →

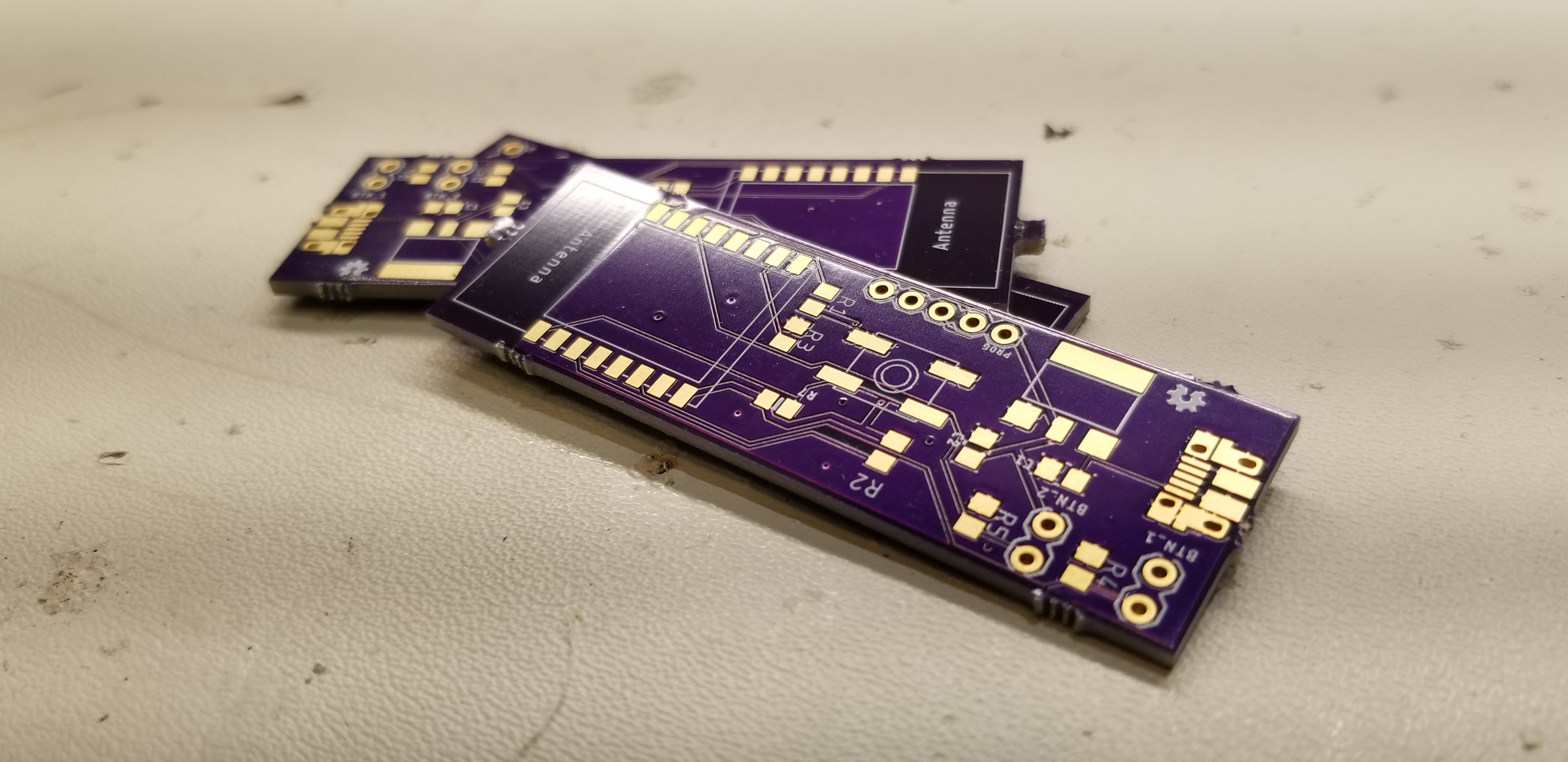

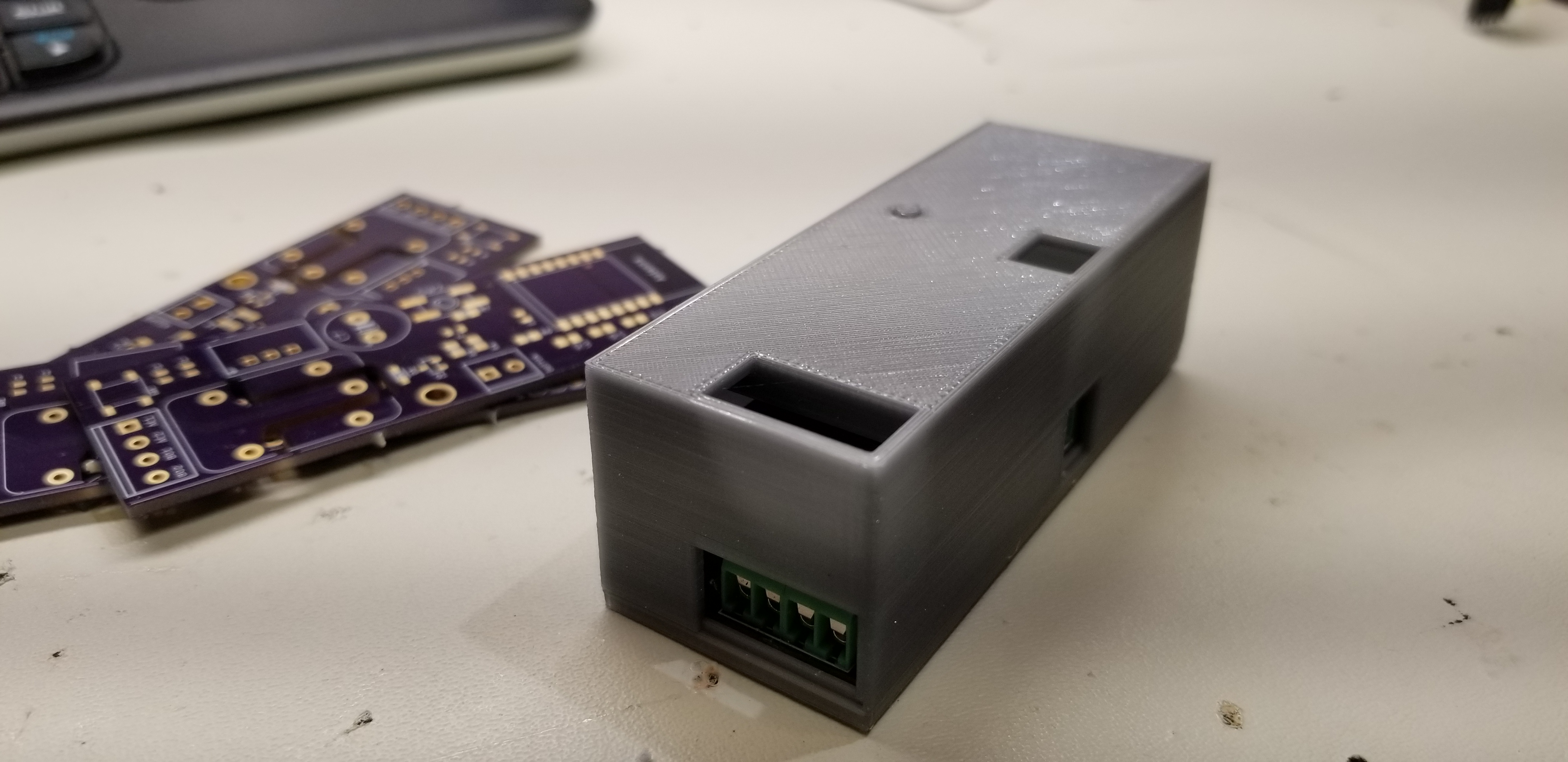

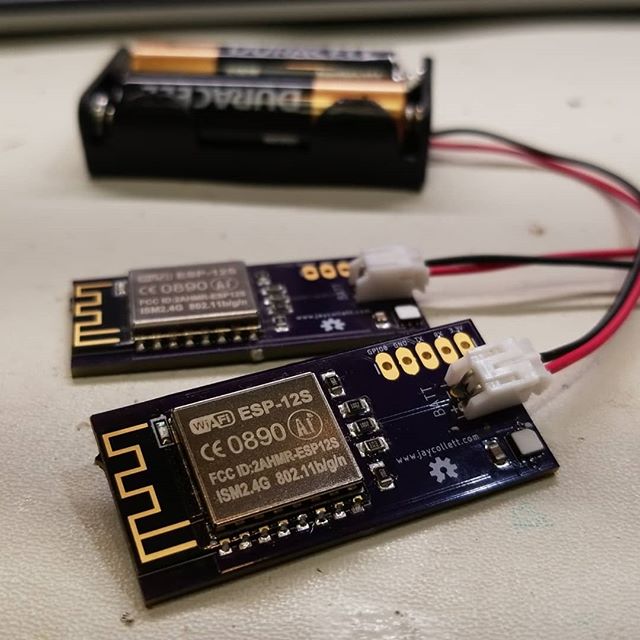

I finally finished what I’d call a satisfactory version of my filament sensors. I’ve wanted an affordable, accurate, and geeky way to monitor the humidity inside the storage boxes I use to store all my 3D printing filament. I couldn’t… Continue Reading →