Category Arduino

Several years back, I got into the home automation game, sadly for me, at the time I was trying to automate “all the things”, it was just too chaotic lacking any standardization, was severely limited in what you could do,… Continue Reading →

In my last post I talked about an issue my company had. We couldn’t monitor our paging infrastructure from end-to-end and we couldn’t find anybody selling anything that could. Before folks start yapping about pagers, you will see them in… Continue Reading →

I’ve slowly been able to expand my home lab to include the type of equipment that allows me to continually improve my technical skills as well as experiment with home automation and DIY electronics. As my home lab has grown so has the need… Continue Reading →

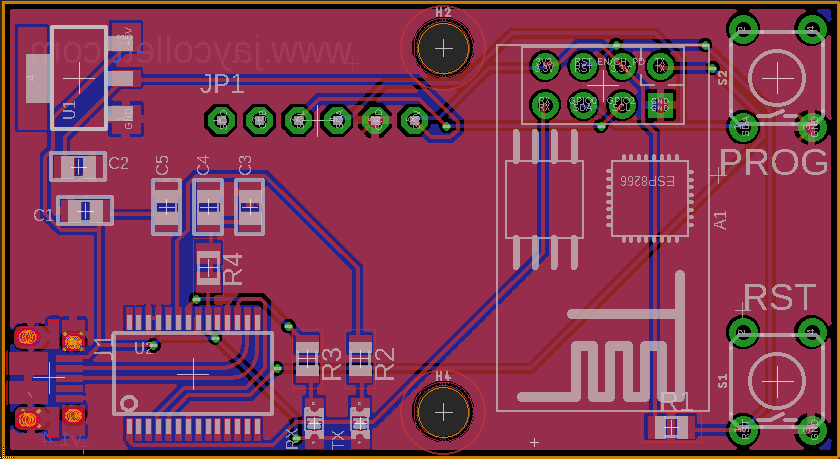

I’ve recently redesigned my Retro WiFi Radio project to include some “extra” functionality and the design requirements required some tiny spacing of the components in addition to some tiny SMD parts. While I’m all for hand soldering SMD when needed,… Continue Reading →

Update: This board design and firmware were just far too buggy. I was very excited to see the Arduino team had answered everyone’s request with a WiFi shield and it rocks. http://arduino.cc/en/Main/ArduinoWiFiShield Just wanted to let folks know that… Continue Reading →

I’ve been working on this project for some time, I had originally read about the concept of hacking the Asus WL-520GU to use as a base for a wifi radio over at MightyOhm.com. In fact, I was so taken by… Continue Reading →